Offering customers, the best service possible is crucial for a business to prosper. Every action, including manufacturing orders, deliveries, receptions, and other events, must be planned. To accomplish this, you must properly configure lead time and coordinate scheduled dates.

By using lead times, Odoo 16 CRM provides commitment dates, or end dates, for each process.

According to a sales order, today is the day that your consumers will receive their purchases. From the clients’ point of view, the commitment date is important since it gives them an idea of when they may expect to receive their orders. The dates take into consideration all additional lead times, such as those related to manufacturing, shipping, or suppliers.

There are several lead times, and each is assessed using various metrics.

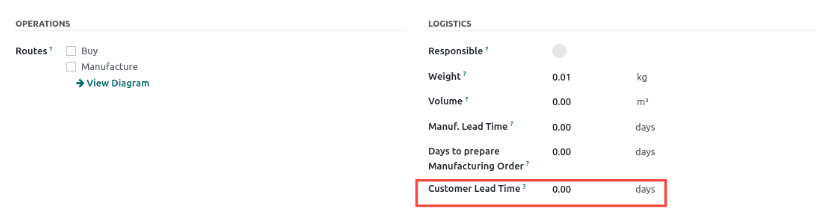

Customer lead time: Customer lead time is the period of time it takes for a business to complete an order from the time it is placed until it is delivered to the customer. The time needed to process the order, manufacture the item (if necessary), package, and ship it to the buyer is included in this.

Sales Security lead time: The goal is to have everything ready for shipment a few days before the customer actually makes a commitment. The SO delivery date less the security lead time is thus the default scheduled date for the delivery order.

Purchase security lead time: The system will generate Purchase Orders for the acquisition order products that are many days sooner than intended in order to accommodate for unanticipated vendor delays.

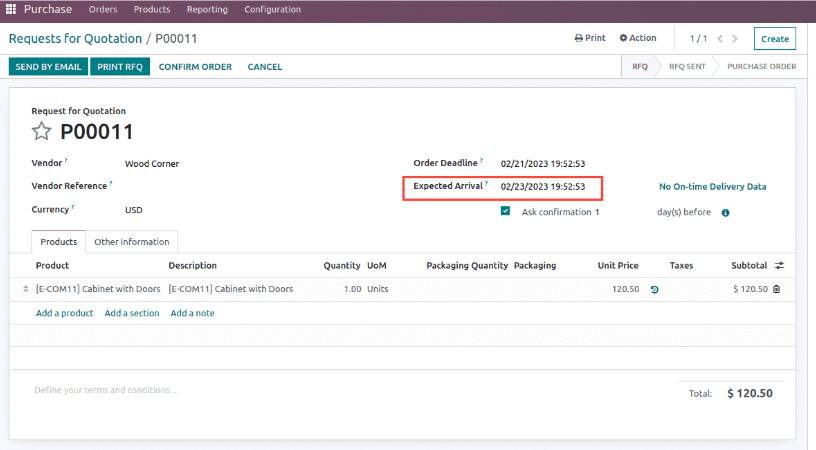

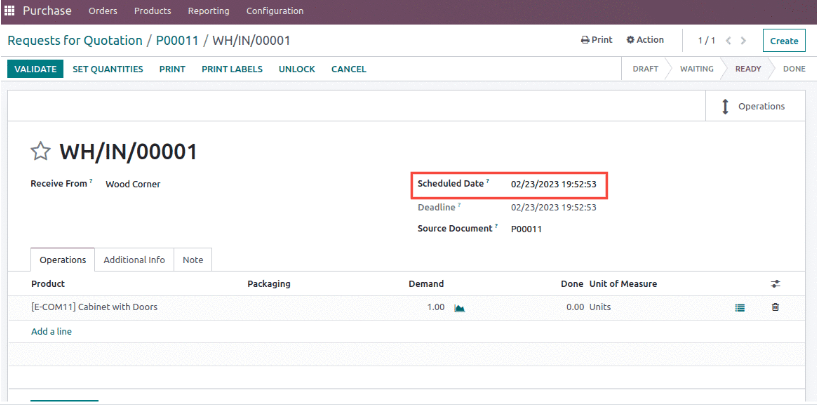

Purchase delivery lead time: This is the time frame that is anticipated to pass between a PO’s confirmation and the delivery of the requested goods. The targeted date for receipt, minus the vendor delivery date is the default PO Order by date.

Date to purchase: The time it takes for a purchase order to be verified by the purchasing department. If a different RFQ to the same vendor has already been opened, Odoo adds the line to the existing RFQ rather than creating a new one. Next, the exact date is written on the line.

Manufacturing lead time: This is a reference to the anticipated length of time required to produce a good. This lead time does not account for routing time and is independent of the quantity to be produced.

Manufacturing security lead time: Additional time to decrease the likelihood of a manufacturing delay.

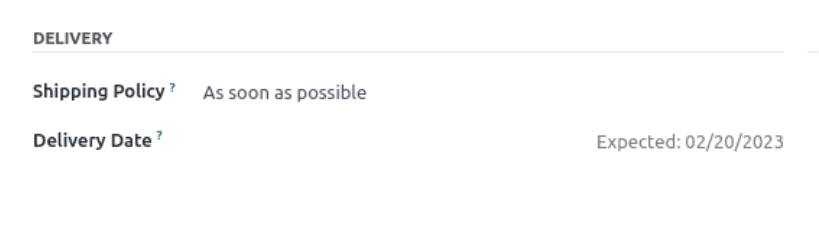

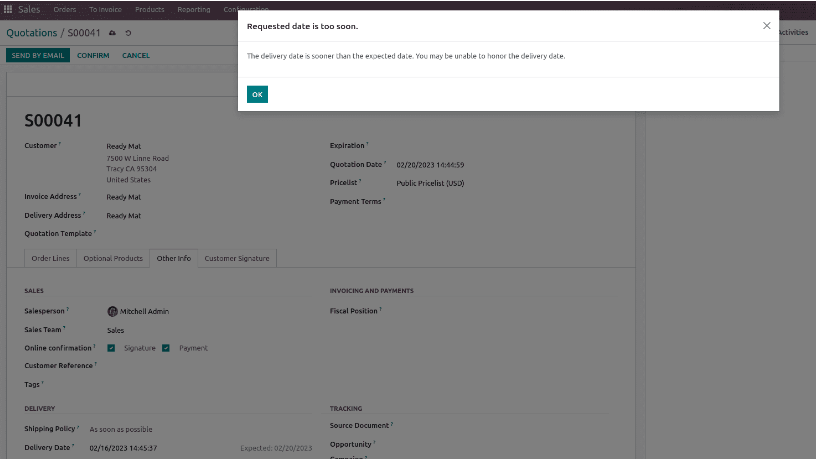

Sales lead time: The delivery date field on sales orders can be mentioned in the sales module, which also makes it possible to view the expected date field. This one is calculated automatically based on the different lead times that were previously defined, as seen in the screenshot below.

Here, a warning message indicating the delivery date is earlier than the anticipated date appears if it is planned before the expected date. The delivery date could be impossible for you to keep.

Customer lead time

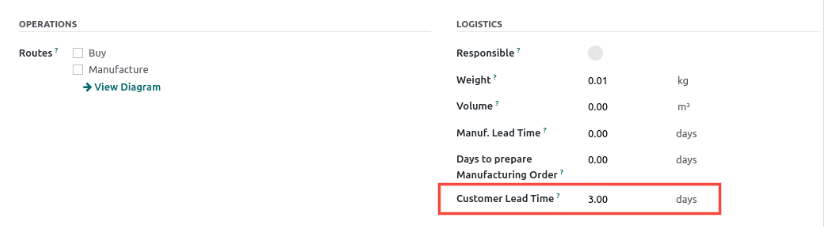

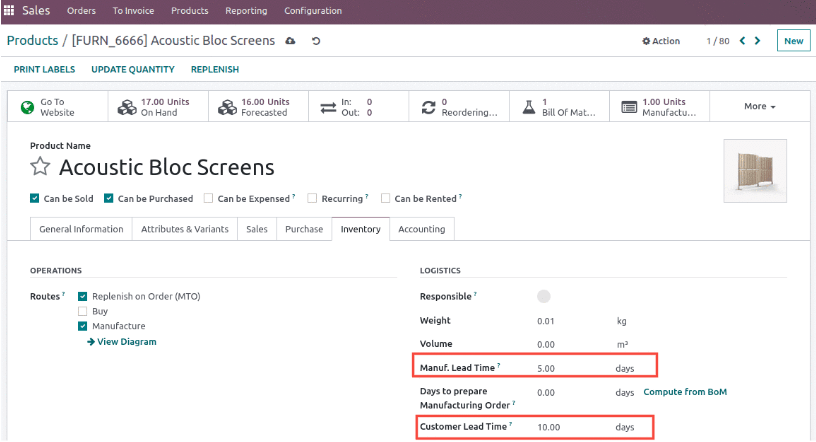

The shortest period of time between the entry of a sales order and the preparation of the product for shipping is called the customer lead time. By navigating to Sales? Products, one can configure the customer lead time under the inventory page independently for each product.

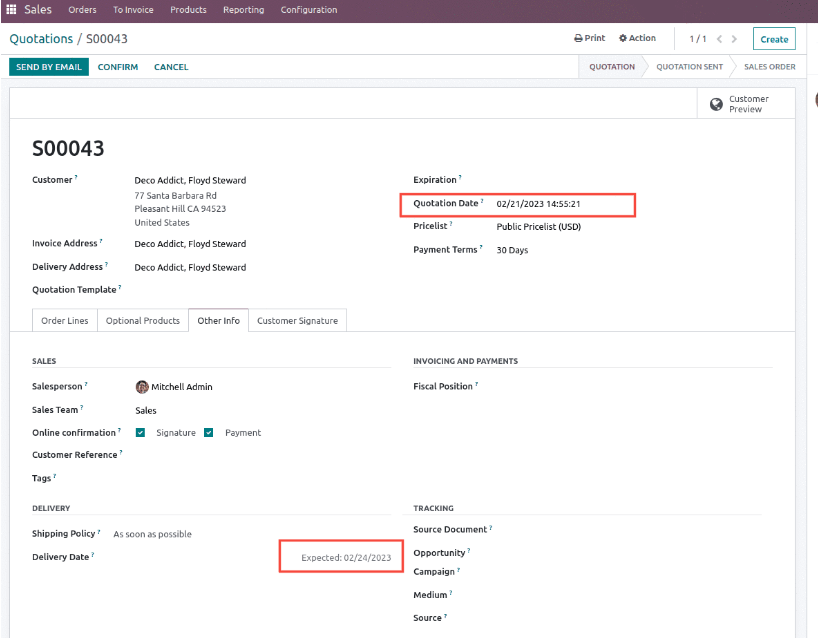

For instance, a buyer orders Acoustic Bloc Screens on February 21 but must wait three days for delivery. In this case, the order is anticipated to leave the premises on February 24 as depicted below.

Security lead time for sales

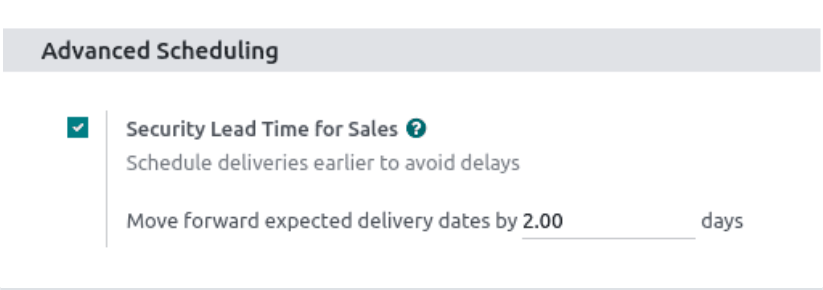

To accommodate for unexpected delays and guarantee that the customer receives their order on time, the Sales module’s Security Lead Time for Sales option adds extra days to the anticipated delivery date. Go to Inventory > Configuration > Settings and turn on the Security Lead Time for Sales setting under Advanced Scheduling at the bottom to enable the feature.

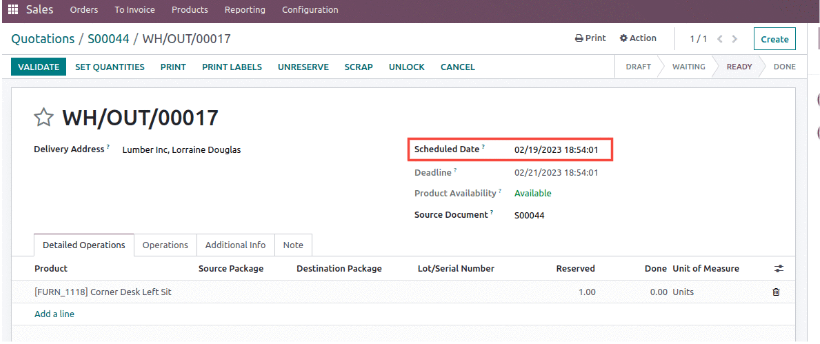

Consider a scenario in which an order is anticipated on February 21 but the security lead time is two days.

In such case, as indicated in the screenshot below, the delivery order is scheduled to arrive on February 19.

Vendor lead time

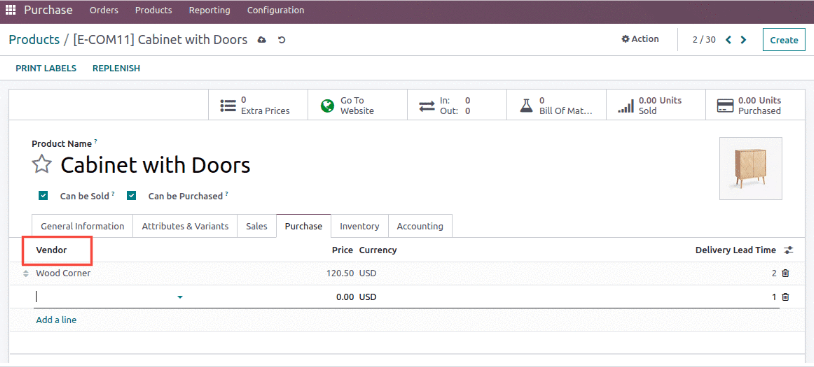

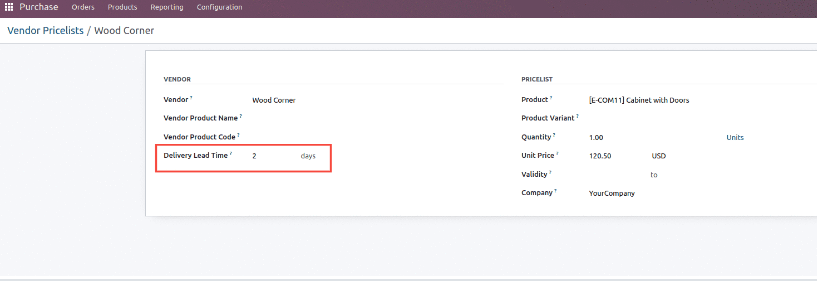

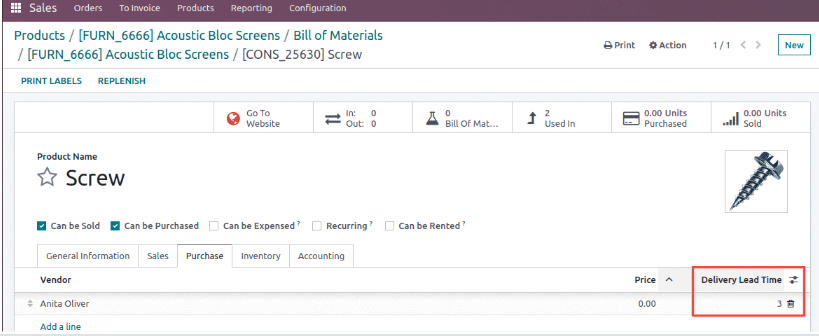

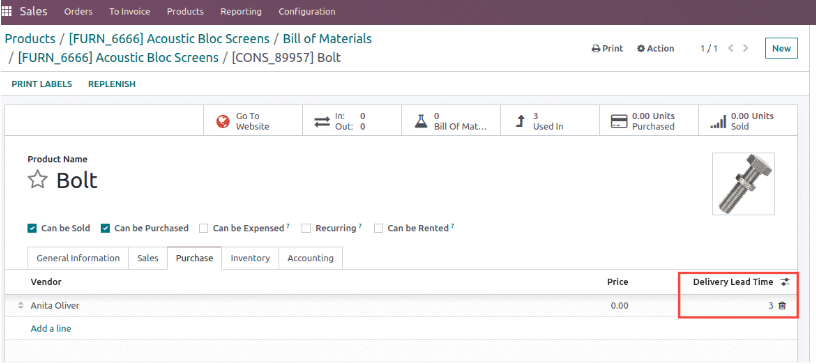

Vendor lead time, also known as purchase lead time, is the period of time needed for a product you ordered to be delivered to you. One can set the suppliers under the product’s purchasing page because it is configured at the product level.

The Delivery Lead Time can be entered in a field on the vendor pricelist page. The delivery day for each order of that product will now be determined, if specified, by the order date of the purchase order plus the delivery lead time. Have this information available if you want to consider delivery speed when placing purchases since different vendors may have different lead times.

The vendor lead time has been set to two days, as can be seen in the image below.

Security lead time for purchase

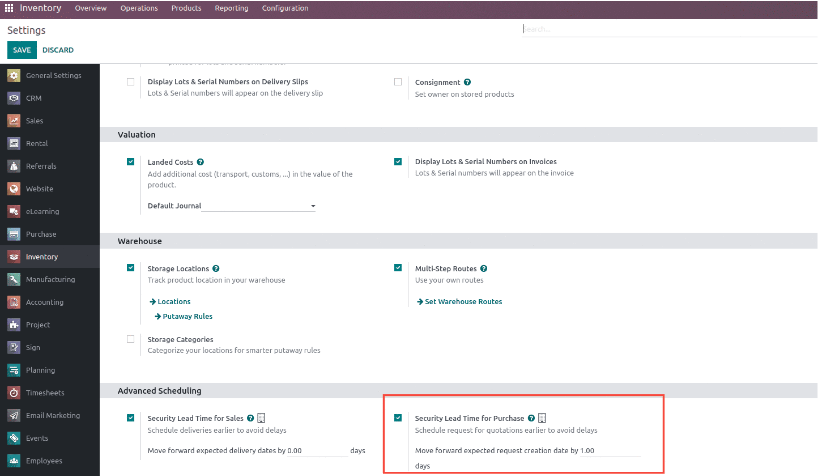

Security Lead Time for Buying operates on the same principle as Security Lead Time for Sales, with the distinction that you, the customer, are the one who keeps track of the extended time your supplier has to complete your order. You should be able to plan for any vendor delays by choosing this date. To configure it, go to Inventory Configuration Settings and enable Security Lead Time for Buying.

Manufacturing lead time

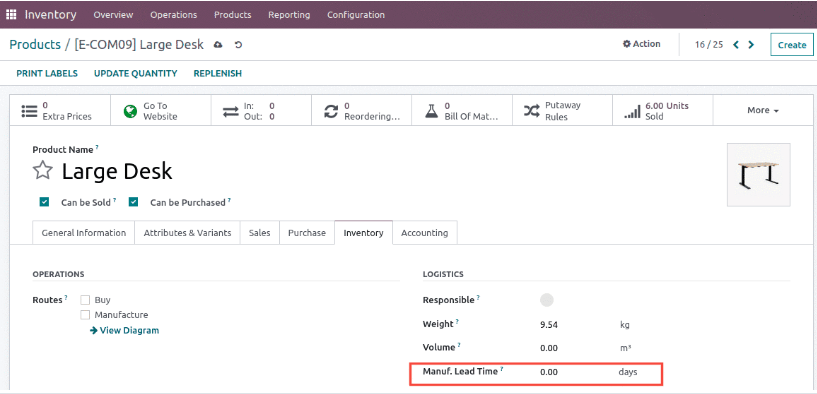

The manufacturing lead time is the period needed to produce the items. You can set this parameter at the product level by choosing the Inventory tab of your product form and inputting the quantity of manufacturing days needed. This allows you to schedule a start date for the order’s manufacturing and aids in helping you prioritize daily tasks.

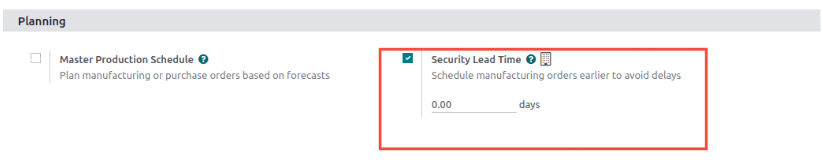

Security lead time for manufacturing

Security lead time is additional time added to minimize the possibility of a manufacturing delay. This helps to adjust for maintenance or administrative delays as well as situations with a high order volume.

The finest possible customer service is essential for business. All actions, such as production orders, delivery, receptions, and so forth, must be scheduled. You must set up planned dates and adjust lead time properly to accomplish this. In a variety of commercial processes, lead time can be employed to manage the operation in the simplest method.

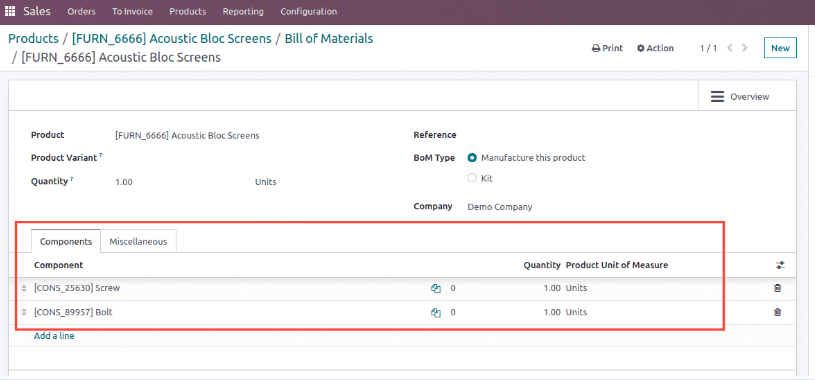

In general, if we take into account a situation where a customer orders a product and it is out of stock and needs to be manufactured, for which we must buy the products’ components from the vendor, this scenario can be effectively managed and delivered to the customers on time with the help of lead time. Let’s use an example where a customer orders a product that is not yet available and must be manufactured. First, let’s create a sale order for the customer. Next, if the product is not yet available and must be manufactured, let’s set the customer lead time. Finally, if the product must be manufactured in order to prevent delays from vendors in receiving the product and manufacturing it, let’s assign the vendor lead time to the components of the sale order.

Because the primary product must be manufactured and its components cannot be found in adequate quantities in stock, they must be ordered from the vendor, so we may set a wait time for those components as well.

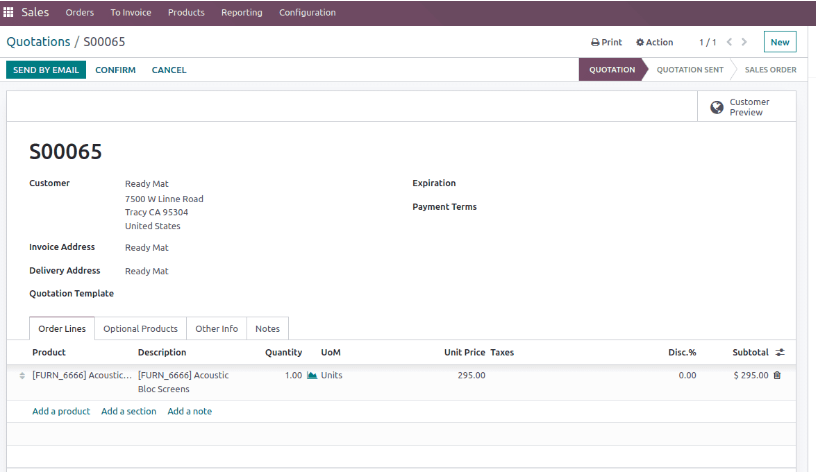

Let’s now construct a sale order for the aforementioned products in the order line with the order date of September 3, 2023, as seen below;

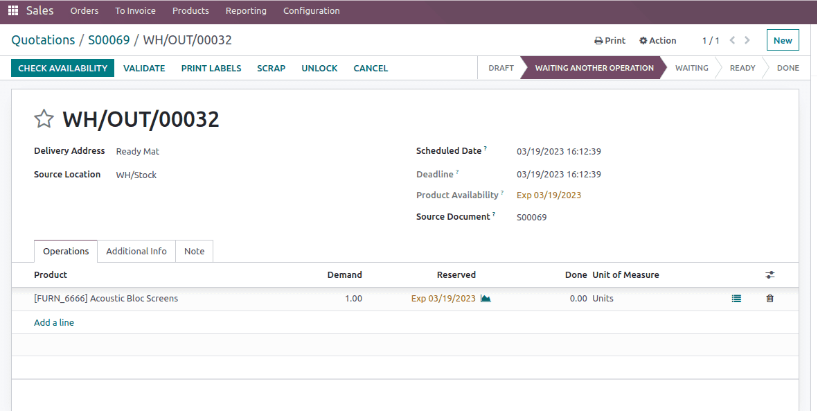

Since the customer lead time was set to 10 days as shown in the screenshot below, once the sale order is confirmed, we can see that the scheduled date has been updated to March 19, 2023.

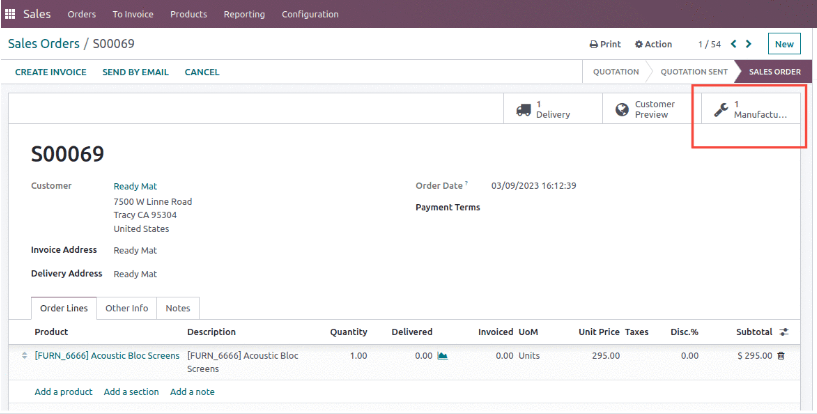

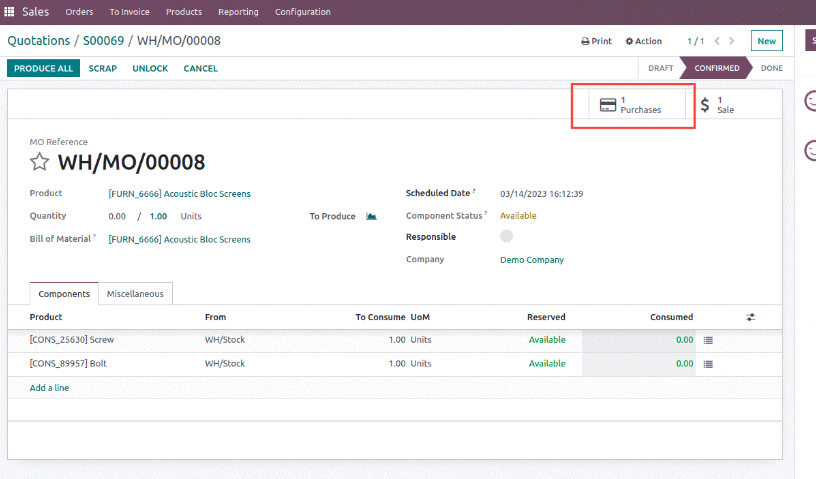

Now that the sale order has been confirmed, we can also see that a new manufacturer smart button has been added. This is because the route for the product has been set to “Manufacture and Replenish on Order” (MTO), and inside the manufacturer smart button, a new purchase order smart button has been created that contains the necessary components to manufacture the product as shown in the screenshot below.

Due to the fact that we added a 5-day manufacturing lead time for this product, it can be seen in the screenshot above that the manufacturing order WH/MO/00008 is expected to be completed on March 14, 2023.

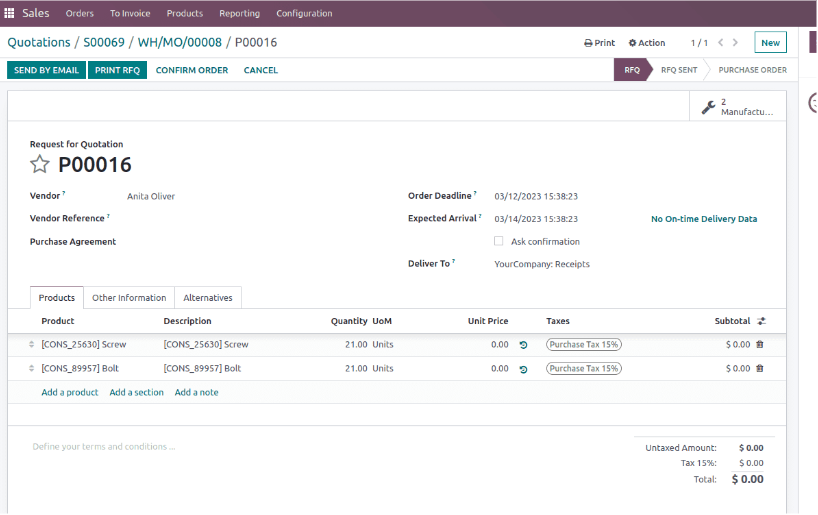

Similar to the Purchase tab, the Order deadline for the purchase order is set to 12/30/2023. This is because the vendor lead time for the components Screw and Bolt is set at 3 days.

So, one can see how the lead time option is used to manage operations extremely successfully and assist the firm run smoothly and conflict-free.

Why choose Odoo 16 CRM?

Odoo 16 CRM is a powerful tool that businesses should consider utilizing to streamline their customer relationship management processes. With its user-friendly interface, extensive features, and flexibility, Odoo 16 CRM provides businesses with a comprehensive solution that can help them manage their sales pipeline, automate their marketing campaigns, and provide excellent customer service.

One of the key advantages of Odoo 16 CRM is its ability to integrate seamlessly with other Odoo applications, allowing businesses to create a unified and integrated system for their entire organization. This can lead to increased efficiency and productivity, as well as improved customer satisfaction.

Moreover, Odoo 16 CRM is constantly updated and improved, ensuring that businesses have access to the latest features and functionality to help them stay competitive in their industries.

Overall, Odoo 16 CRM is a powerful and versatile tool that can help businesses of all sizes manage their customer relationships more effectively and efficiently. With its extensive capabilities and flexibility, Odoo 16 CRM is definitely worth considering for any business looking to streamline its operations and improve its customer experience.