Efficient warehouse management is crucial for ensuring streamlined operations and meeting customer demands. As technology evolves, warehouse management systems (WMS) are pivotal in optimising inventory management, order fulfilment, and overall supply chain efficiency. In this article, we will explore in detail the future of warehouse management systems, emerging trends, and the impact of automation on warehouse operations.

What is the Future of Warehouse Management?

The future of warehouse management is shaped by cutting-edge technologies that enhance efficiency, accuracy, and real-time visibility. Let’s take a closer look at some of the key trends that will define the future of WMS:

Advanced Analytics and AI

Warehouse managers will harness the power of AI and advanced analytics to gain deeper insights into inventory levels, demand forecasting, and resource optimisation. AI-driven WMS will enable data-driven decision-making and improve operational efficiency.

Internet of Things (IoT) Integration

The IoT will revolutionise warehouse management by enabling real-time tracking of inventory, equipment, and vehicles. IoT sensors and devices will provide data on stock levels, temperature, and conditions, ensuring better inventory control and reducing the risk of stockouts.

Blockchain for Supply Chain Transparency

Blockchain technology will be integrated into WMS, enhancing supply chain transparency, traceability, and security. The decentralised nature of blockchain will enable secure data sharing among stakeholders and facilitate end-to-end supply chain visibility.

Robotics and Automation

Using robotics and automation in warehouse operations will continue to expand. Robots will assist in order picking, packing, and inventory management, increasing productivity and reducing manual errors.

What is Automation in the Warehouse?

Warehouse automation involves using advanced technology to perform tasks traditionally carried out by human labour. Automation offers several benefits to warehouse operations:

Improved Efficiency

Automated systems can execute tasks faster and more accurately than manual processes, leading to increased efficiency in warehouse operations. With the ability to handle repetitive tasks, automation allows employees to focus on more strategic roles.

Reduced Labor Costs

Businesses can optimise labour costs and allocate human resources to more value-added activities by automating repetitive tasks. This cost-effectiveness is particularly advantageous for companies with large-scale warehousing operations.

Error Reduction

Automation minimises the risk of human errors in inventory tracking, order picking, and shipping, leading to improved order accuracy and customer satisfaction.

What Should Companies Focus on in 2023?

As we approach 2023, companies aiming for success in the warehousing domain should focus on the following key areas:

Adopting Integrated WMS Solutions

Adopting an integrated Warehouse Management System (WMS) solution is paramount for businesses looking to optimise their warehouse management processes. Integrated WMS connects with other business systems, such as Enterprise Resource Planning (ERP) software, to create a unified and cohesive operational environment. This integration ensures data synchronisation and real-time information sharing between different departments, enabling smoother and more efficient operations.

By integrating WMS with ERP systems, businesses gain a holistic view of their supply chain, from procurement to order fulfilment. This comprehensive visibility allows for better demand forecasting, accurate inventory tracking, and improved resource planning. Data synchronisation across systems reduces the risk of discrepancies and errors, improving overall efficiency and decision-making.

Scalability of Solutions

As businesses grow and expand, their warehouse management also needs to evolve. Scalability becomes a critical consideration when choosing warehouse management software. Scalable WMS solutions can adapt and expand along with the company’s operations, accommodating increasing inventory volumes and the complexities of business growth.

Scalable WMS ensures that businesses can handle larger order volumes, diverse product lines, and an expanding customer base without experiencing major disruptions or the need for extensive system overhauls. This flexibility allows businesses to remain agile and responsive to market demands, enabling them to seize new opportunities and stay competitive.

User-Friendly Interfaces

The usability of WMS interfaces plays a crucial role in ensuring successful implementation and adoption within a company. A user-friendly interface is intuitive, easy to navigate, and requires minimal employee training to use the system effectively.

Prioritising WMS solutions with user-friendly interfaces reduces the learning curve for employees, increasing their productivity and reducing the chances of errors during daily operations. Intuitive interfaces also empower users to access critical information quickly, make informed decisions, and execute tasks efficiently.

A user-friendly WMS interface enhances employee satisfaction and engagement, leading to higher adoption rates and smoother transitions during system implementation. This, in turn, contributes to the overall success of the warehouse management system and the company’s operations.

What are the Warehouse Management Trends in 2023?

In 2023, the warehouse management landscape will witness several trends that are poised to shape the industry:

AI-Driven Predictive Analytics

AI-powered Warehouse Management Systems (WMS) are set to transform how businesses handle their inventory and supply chain operations. By analysing historical data and market trends, AI-driven WMS can predict demand fluctuations more accurately. This proactive approach to inventory management will help businesses adapt quickly to changing market conditions, ensuring they can meet customer demands efficiently.

With AI-driven predictive analytics, businesses can optimise inventory levels, preventing stockouts and overstock situations. By anticipating future demand, companies can plan their procurement and production processes more effectively, reducing lead times and improving overall supply chain efficiency. AI-powered WMS will provide valuable insights into product demand patterns, enabling businesses to make data-driven decisions and allocate resources more efficiently.

Robotics and Autonomous Vehicles

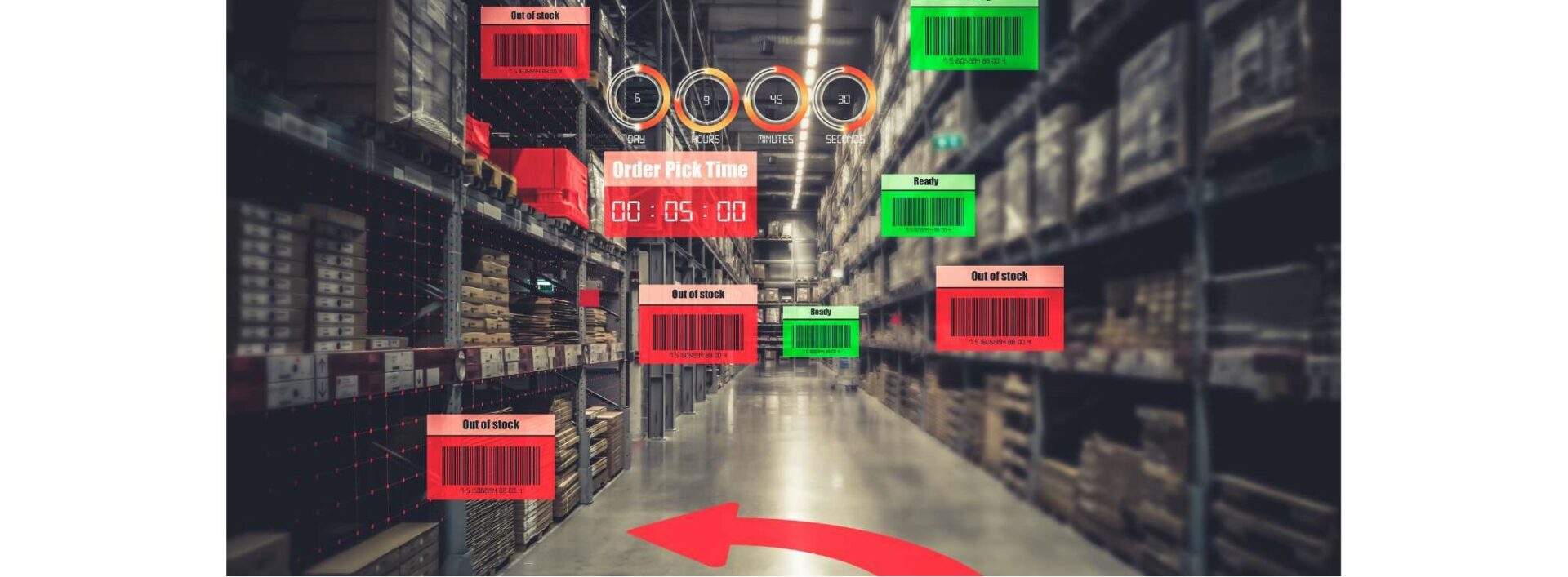

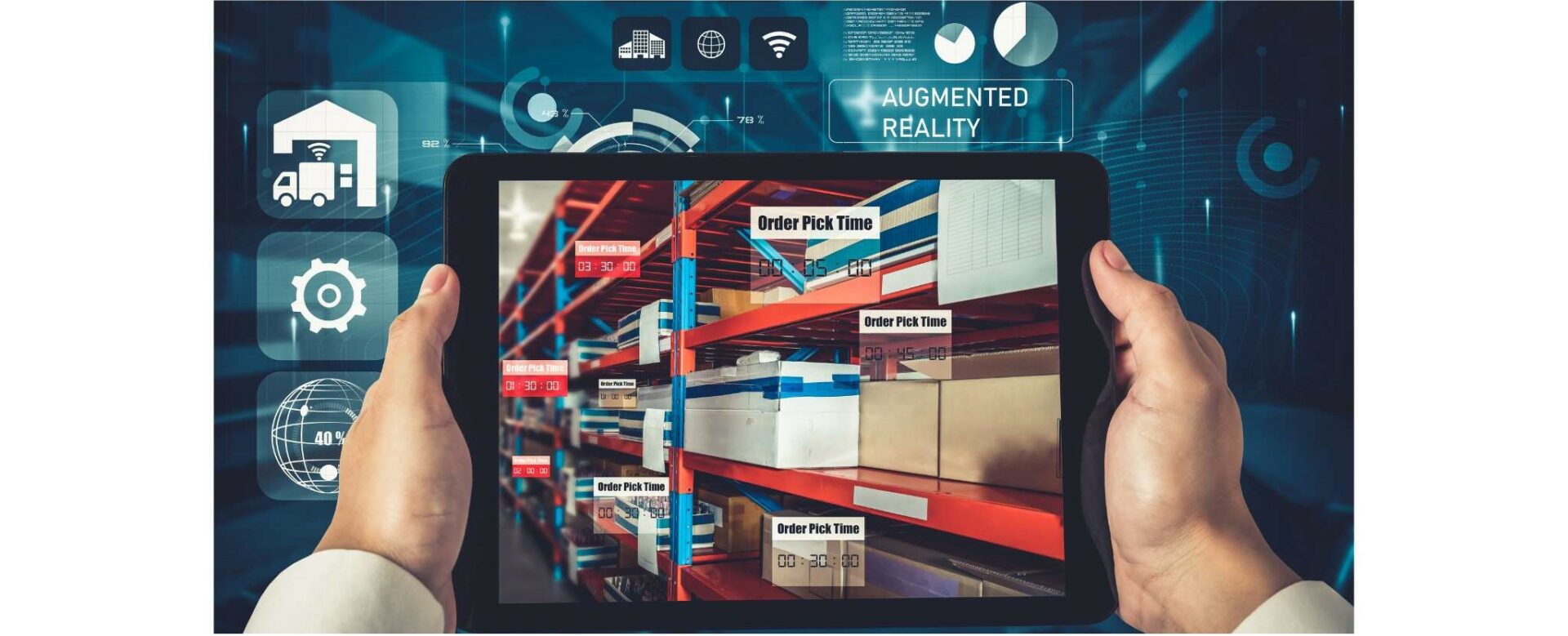

Integrating robotics and autonomous vehicles in warehouse operations is poised to revolutionise order fulfilment processes. Robotics and automation technologies will enhance the speed and accuracy of tasks like order picking, packing, and sorting. By reducing the reliance on manual labour, businesses can achieve higher productivity and operational efficiency.

Robots equipped with advanced sensors and vision systems can navigate through the Warehouse autonomously, reducing the need for human intervention and minimising errors in the order fulfilment process. This increased automation will improve order accuracy and lead to faster processing times, enabling businesses to meet tighter delivery deadlines and customer expectations.

Furthermore, autonomous vehicles will play a significant role in material handling within the Warehouse. Automated guided vehicles (AGVs) and drones will transport goods from one location to another, optimising internal logistics and reducing the time to move inventory within the Warehouse. Integrating robotics and autonomous vehicles will enable businesses to achieve a seamless and highly efficient warehouse operation.

Cloud-Based WMS

Cloud-based Warehouse Management Systems (WMS) are gaining widespread popularity due to their numerous benefits for businesses of all sizes. One of the key advantages of cloud-based WMS is its flexibility, as it allows businesses to scale their operations easily. Whether a company experiences seasonal fluctuations in demand or rapid growth, cloud-based WMS can adapt to varying inventory levels and order volumes.

In addition to being cost-effective, cloud-based WMS eliminates the need for extensive IT infrastructure and maintenance costs. Businesses can access their WMS data in real time from any location with an internet connection, enabling better collaboration among geographically dispersed teams. Cloud-based solutions offer seamless updates and upgrades, ensuring that businesses always have access to the latest features and functionalities without the hassle of manual installations.

Moreover, cloud-based WMS provides enhanced data security, with reputable providers implementing robust security measures to safeguard sensitive information. This allows businesses to focus on their core operations without worrying about data breaches or downtime due to hardware failures.

What is the Future of Warehousing in India?

The future of warehousing in India looks promising, driven by several factors:

Rapid E-Commerce Growth

The e-commerce sector in India has been experiencing remarkable growth in recent years. With the increasing popularity of online shopping and the rise of digital marketplaces, there is a surge in consumer demand for faster and more efficient deliveries. As a result, warehousing facilities will need to adapt to handle higher volumes of inventory and process orders faster and more accurately.

Government Initiatives

Government policies play a crucial role in shaping the warehousing landscape in India. Implementing the Goods and Services Tax (GST) has led to the developing of organised warehousing infrastructure across the country. The unified tax system has eliminated inter-state barriers, making it easier for businesses to streamline their supply chains and establish warehouses strategically to serve different regions more effectively.

Adoption of Technology

To keep up with the evolving market demands and to address the complexities in supply chain management, Indian warehousing is expected to witness significant adoption of Warehouse Management Systems (WMS) and automation technologies. WMS will enable businesses to optimise inventory, improve order fulfilment processes, and enhance warehouse efficiency. Automation technologies like robotics and autonomous vehicles will be integrated into warehouses to automate tasks like order picking, packing, and inventory management. This shift towards automation will help businesses reduce labour costs, minimise errors, and improve warehouse productivity.

Conclusion

As we move into the future, warehouse management systems will continue to evolve and shape the supply chain landscape. By embracing advanced technologies, automation, and integrated WMS solutions, businesses can optimise their warehouse operations, improve customer satisfaction, and stay ahead of the competition. Whether a large enterprise or a small business, finding the right warehouse management software provider will be instrumental in achieving success in the rapidly changing logistics industry. By staying informed about emerging trends and innovations, companies can prepare for exciting opportunities in warehouse management. The future holds immense potential for those who adapt, innovate, and leverage technology to transform their warehousing operations.

Moreover, Target Integration recognizes the significance of scalability in warehouse management software. As your business grows, your warehousing needs evolve, necessitating a WMS that can accommodate increasing inventory volumes and order complexities. The team at Target Integration is well-versed in identifying scalable WMS solutions that will grow along with your business, allowing you to adapt to changing market demands without disruptions.