Having a supply chain process that consistently results in difficulties and setbacks is something you may be sick of managing. Look nowhere else! Your supply chain process can be streamlined to improve management and procurement, which will result in a more effective and economical operation. We’ll go over the best practices for optimizing your supply chain in this blog article so you can concentrate on expanding your business rather than fretting about logistics. So, let’s explore the procurement industry and enhance your supply chain management right now!

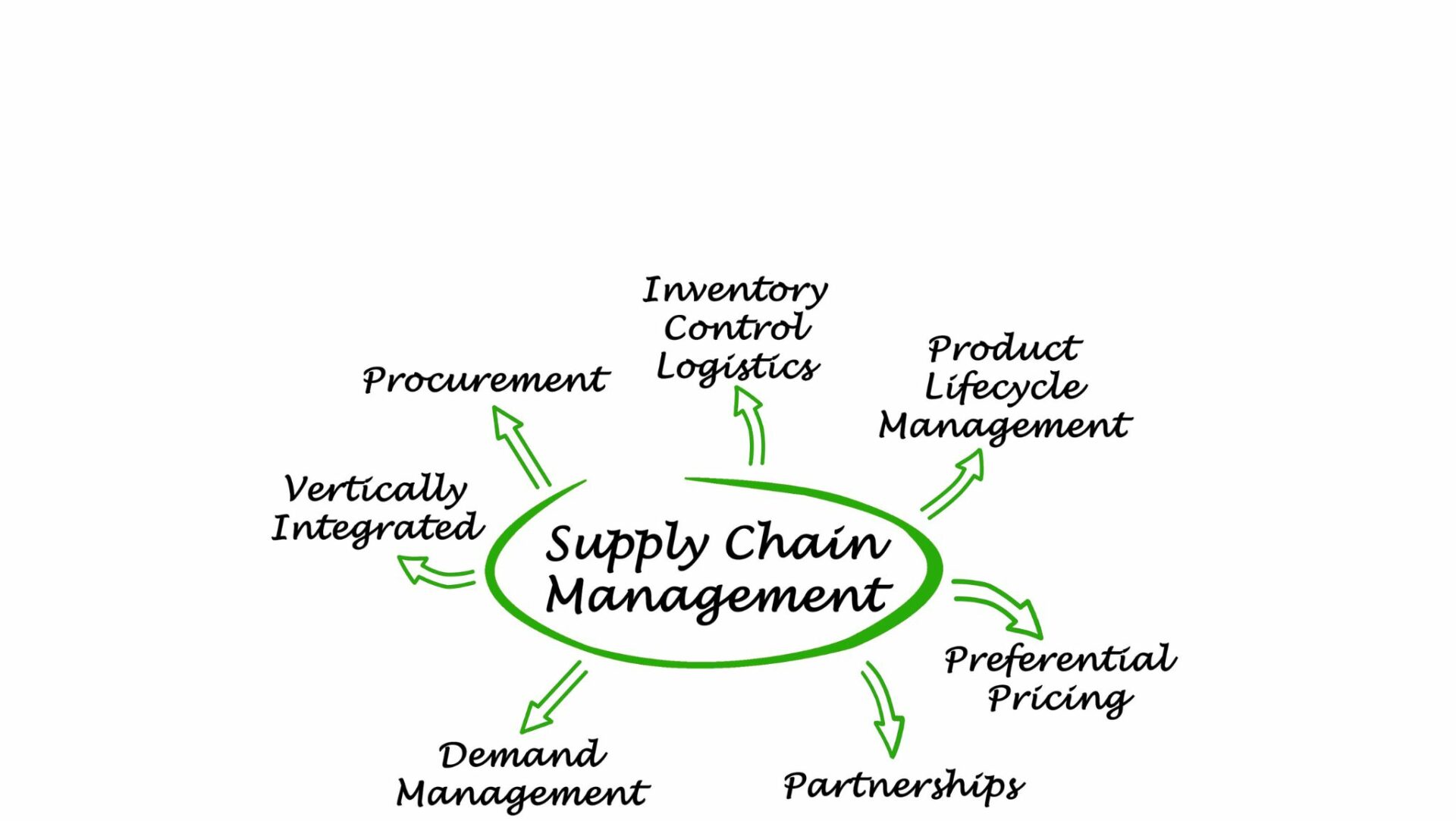

What is a Supply Chain?

A supply chain is a system of businesses, people, events, information, and assets involved in the production and distribution of a good or service in order to satisfy consumer needs. It includes every stage, from locating raw materials to shipping finished products to the final customer.

Typically, procurement is the first step in the process, during which suppliers are contacted for raw materials. These raw components are then manufactured or put together to create finished goods, which proceed to distribution centers for storage before being delivered to merchants.

A properly managed supply chain process can guarantee that goods are supplied quickly, cheaply, and effectively. However, any interruptions in the supply chain, such as sluggish quality control or delayed delivery, can result in delays and higher expenses.

Understanding your company’s supply chain is critical for spotting problems and pinpointing places where procedures may be streamlined, and costs can be cut while still upholding high standards. This is where effective supply chain management comes into play, which we’ll discuss in more detail later in this article.

What is a Supply chain process?

A supply chain process refers to the series of interconnected activities and steps involved in the production, distribution, and delivery of goods or services from the initial raw material sources to the end consumer. It encompasses all the stages and interactions required to create and deliver a product to the market. The goal of an effective supply chain process is to optimize efficiency, reduce costs, and ensure timely delivery while maintaining the desired level of product quality.

The typical stages of a supply chain process include:

- Planning: This involves forecasting demand, setting production goals, and developing strategies for procurement, manufacturing, and distribution. It’s about making informed decisions about how much to produce, when to produce, and how to allocate resources efficiently.

- Sourcing: This phase entails identifying and selecting suppliers for raw materials, components, or finished goods. Negotiating contracts, establishing relationships, and managing supplier performance are crucial aspects of this stage.

- Manufacturing/Production: This step involves converting raw materials or components into finished goods. It includes processes such as manufacturing, assembly, testing, and quality control.

- Inventory Management: This stage focuses on maintaining an appropriate level of inventory to meet customer demand while avoiding excess inventory costs. Balancing stock levels with demand fluctuations is a key challenge in this phase.

- Distribution/Logistics: Once products are manufactured, they need to be transported to distribution centers or directly to retailers and customers. Efficient transportation, warehousing, and order fulfillment processes are vital to ensure timely delivery.

- Retail/Point of Sale: If the supply chain involves consumer goods, this phase involves interactions with retailers and ultimately the end customers. It includes activities such as product placement, pricing, promotions, and customer service.

- Customer Experience: Providing a positive customer experience is critical to a business. This involves ensuring products are delivered on time, in good condition, and meeting customer expectations. Post-sale services and support also play a role in enhancing customer satisfaction.

- Returns/Reverse Logistics: In case of product defects, customer returns, or other issues, a well-defined process for handling returns and reverse logistics is necessary. This phase focuses on managing returns efficiently while minimizing costs and optimizing value recovery.

Modern supply chain processes are often complex and involve multiple stakeholders, global networks, and the use of technology to improve visibility, communication, and decision-making. Supply chain management software and technologies like RFID, IoT, and advanced analytics have significantly transformed the way supply chains operate, making them more agile and responsive to changing market dynamics.

What is Supply chain Efficiency?

The ability of a company to leverage resources, technology, and knowledge in order to reduce logistical costs and increase revenues is known as supply chain efficiency. By streamlining the operations and stages of the supply chain, an efficient supply chain aims to minimize costs and maximize revenues.

What distinguishes supply chain effectiveness from supply chain efficiency?

Supply chain effectiveness is the external standard of performance, whereas supply chain efficiency is the internal measure of performance for a company. In other words, supply chain efficiency refers to addressing those requests as fast and efficiently as possible. Supply chain effectiveness, on the other hand, focuses on meeting the demands of organizations outside your firm.

What is Supply Chain Responsiveness?

The capacity to respond swiftly to unexpected changes in the environment that have an impact on your logistics procedures is referred to as supply chain responsiveness. Examples include being able to scale up when the COVID-19 pandemic struck (i.e., meeting demand for more than twice as many orders as usual when lockdowns were implemented) or shipping inventory quickly during the time when some of the busiest ports in the world were completely overwhelmed with container ship congestion.

Responsive vs Efficient Supply chain process

While supply chain responsiveness is concentrated on agility and maintaining operations when things don’t go as expected, supply chain efficiency is concentrated on getting more done with less. However, since supply chains are some of the most volatile and delicate things in business, efficiency and reactivity in the supply chain work together to manage ongoing chaos.

At the end of the day, what matters is a unified supply chain that can move swiftly and change without suffering financial loss, not whether it is efficient or responsive. Common metrics to keep an eye on in effective and responsive supply chains include on-time fulfillment, profit margins, shipping rates, lead times, and more. Meeting customers’ expectations is their shared objective.

Significance of streamlining your supply chain process

Streamlining your supply chain process entails optimizing these operations to make them more efficient, cost-effective, and customer responsive. This can assist you in lowering waste, enhancing quality control, and boosting revenue. A streamlined supply chain process is essential in the fast-paced business world, where there is fierce rivalry and clients demand quick turnaround times for their goods. You can make sure that your products are delivered on schedule and with minimal errors by doing this.

Streamlining your supply chain process is crucial for several reasons, as it can bring about numerous benefits for your business. Here are some of the key reasons why companies strive to optimize and streamline their supply chain processes:

- Cost Efficiency: An optimized supply chain reduces unnecessary steps, delays, and inefficiencies, which in turn reduces operating costs. Streamlining processes can lead to better resource utilization, reduced inventory holding costs, and minimized transportation expenses.

- Improved Customer Satisfaction: A streamlined supply chain ensures timely delivery of products, reduces lead times, and minimizes order errors. This leads to improved customer satisfaction and loyalty, as customers receive the products they need when they need them.

- Faster Time-to-Market: Efficient supply chain processes enable faster production and distribution, which is especially important when launching new products. Reduced lead times allow businesses to respond more quickly to market trends and customer demands.

- Enhanced Agility and Flexibility: A streamlined supply chain is more agile and adaptable to market changes and disruptions. By optimizing processes, companies can adjust production levels, sourcing strategies, and distribution channels more effectively in response to changing market conditions.

- Better Inventory Management: Streamlining supply chain processes helps in optimizing inventory levels. Businesses can reduce excess stock while ensuring they have enough inventory to meet demand. This leads to improved cash flow and reduces carrying costs.

- Supplier Relationship Management: A well-organized supply chain process enables better communication and collaboration with suppliers. This can lead to stronger partnerships, better negotiation outcomes, and improved overall supplier performance.

- Reduced Risk and Resilience: Streamlining the supply chain often involves identifying potential risks and vulnerabilities. By addressing these risks, companies can build a more resilient supply chain that is better equipped to handle disruptions, such as natural disasters, geopolitical issues, or supply shortages.

- Data-Driven Insights: Modern supply chain optimization often involves using data analytics to gain insights into various aspects of the supply chain. These insights can help in making informed decisions related to production, distribution, demand forecasting, and more.

- Waste Reduction: A streamlined supply chain process can help identify areas of waste, such as overproduction, excess inventory, and inefficient transportation routes. By addressing these inefficiencies, companies can reduce waste and operate in a more environmentally friendly manner.

- Competitive Advantage: A well-optimized supply chain can become a source of competitive advantage. Companies that can consistently deliver high-quality products on time and at a competitive cost have a better chance of outperforming their competitors in the market.

What are the best practices to streamline the Supply Chain Process?

Analyzing and simplifying the supply chain process is one approach to help businesses adapt more rapidly to market changes while increasing operational efficiency. Here are five easy measures that can lead to operations that are more effective, lucrative, and adaptable.

Review and improve supply chain operations

Performing a comprehensive process assessment holds great importance in delineating the current state of the company’s operations and identifying remedies to streamline the intricacies of supply chain management. Supply chain integration can assist in identifying the points in the process where issues are happening, allowing companies to take targeted action to further cut costs and pass savings forward to their customers.

From A to Z, integrate supply chain data

The enterprise resource management system, sales projections, manufacturing resource planning systems, and financial systems are just a few of the systems that are generally involved in every transaction. Information frequently needs to be exchanged with parallel systems held by clients, business partners, and suppliers.

The removal of duplicate data

Duplicate data input processes are removed, saving labor hours and time while creating a system that is simpler to maintain. Data entry can now be done in the field thanks to the introduction of tablets and smartphones in the workplace, which has sped up information flows and enhanced customer service.

Utilize current systems

Many internal systems that have been in use for a while could be stiff, complex, difficult to operate, and difficult to combine with more modern systems. But they may still make good use of a lot of the data they collect for planning and research. Data from current information systems, for instance, can be used to create a mobile supply chain.

Plan ahead

Businesses that streamline their supply networks are better able to see beyond tactical order fulfillment to anticipate future client needs. Analyzing and simplifying the supply chain is a learning process for improving customer service in the future as well as product deliveries today.

What are the benefits of Streamlining your Supply chain process?

Cost savings

Your company stands to gain a lot by streamlining its supply chain process. Cost Efficiency is one of the most major benefits. You may cut costs on purchase, shipping, and storage by streamlining and improving your procurement process.

Improved Efficiency

Improved efficiency is a benefit of optimizing your supply chain. You can shorten lead times and enhance client delivery times with a simplified approach in place. This will improve your ability to meet customer demand and their happiness with your goods or services.

Increased Transparency

Increasing transparency throughout the supply chain process as a result of streamlining enables improved risk management for both supplier relationships and quality control. Companies can respond swiftly to problems when they arise by having complete end-to-end visibility and ensuring that all team members have access to real-time data.

Advanced Risk Management

Modern technology, such as automation software solutions, makes it possible to streamline processes and optimize them much more quickly than with traditional methods, giving organizations more flexibility to respond effectively to unforeseen events or natural disasters.

Final Words

Optimizing your supply chain is crucial to enhance procurement and management functions. The strategies outlined in this article offer valuable insights into refining your supply chain operations, leading to cost reduction and heightened efficiency.

It’s important to recognize that each organization has its distinct requirements for supply chain management. Hence, a meticulous evaluation of your business needs is vital, allowing you to tailor an approach that aligns perfectly with your operations.

Through the integration of these best practices and the ongoing monitoring of performance indicators, you have the potential to make substantial enhancements in various aspects, such as inventory management, order fulfillment speed, transportation logistics, supplier partnerships, and more.

It’s essential to note that streamlining your supply chain isn’t a one-off endeavor; it’s a continuous journey of refinement. Embrace the mindset of continuous improvement and don’t hesitate to experiment with new strategies and technologies that could further elevate your operations. With persistent dedication to optimizing procurement processes and overall supply chain management, success is a natural outcome.