Because of our fast-paced society, businesses increasingly face a number of operational issues. Also, handling the operational restrictions becomes more difficult every day. As a result, every new company increases the level of competition. Due to the limitations of the epidemic, the commercial and logistics sectors have experienced considerable operating reductions.

The business resumed operations once things had calmed down.

The intense competition, the economic downturn, and the difficulty of getting back to business as usual are all waiting for them. As a result, in the event of difficulties, the company will want specialist operating tools that can handle any situation with ease.

Odoo Inventory Management is capable of managing thousands of different types of transactions. It enables companies to successfully manage their inventory of goods or assets. Odoo Inventory Management is a warehouse management system with integrated inventory and tracking. With the use of the Odoo Inventory Management Module, you might be able to manage your warehouse, vendors, buy flow, etc.

This well-known Odoo application handles crucial duties for companies whose operations rely on effective inventory management, particularly those in retail or wholesale, manufacturing, or shipping; as a result, its significance can vary. Its smart inventory characteristics, facilitation of productive working, diversified warehouse management, forecasting abilities, etc. are beneficial to businesses like Retailers and Manufacturers.

Automatic Batch transfer

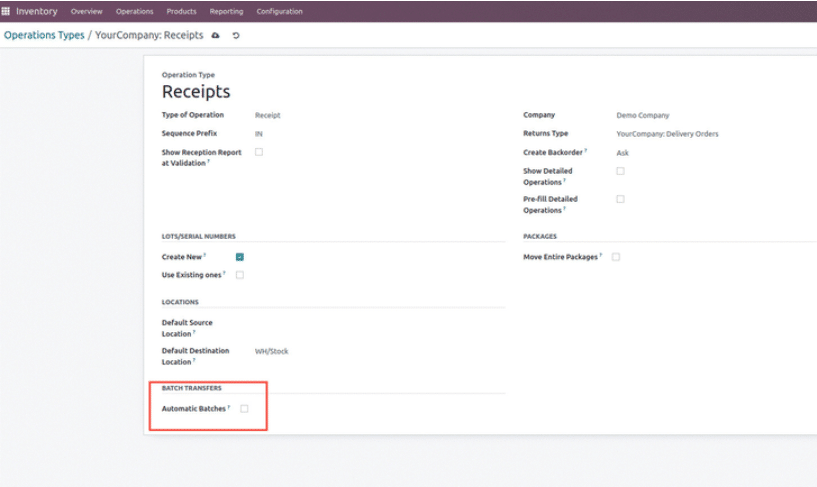

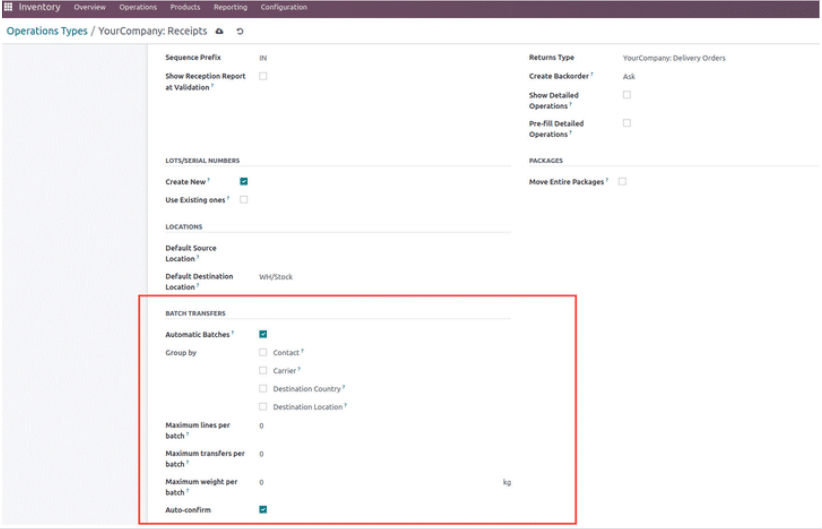

At the level of Operation Types, Automated Batch Transfers assist in determining whether to automate the generation of batches per contact, carrier, or destination nation.

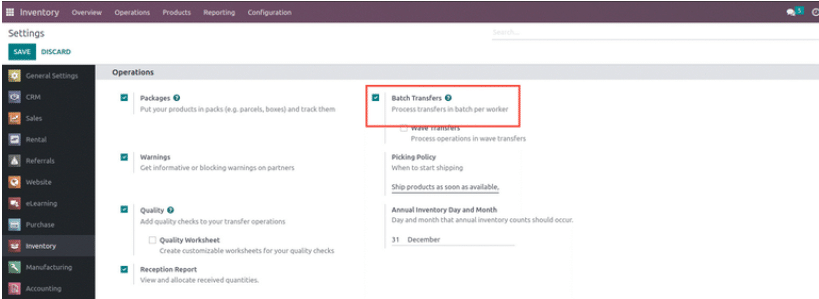

A picker can utilize batch picking, which reduces the number of times he must return to the same area, to enable batch transfer. To enable batch transfer, go to the settings of the inventory module and under Operation, we can see a field to enable Batch transfer. This allows you to conduct several transfers using the form view or the barcode application in Odoo by combining them into a single batch transfer.

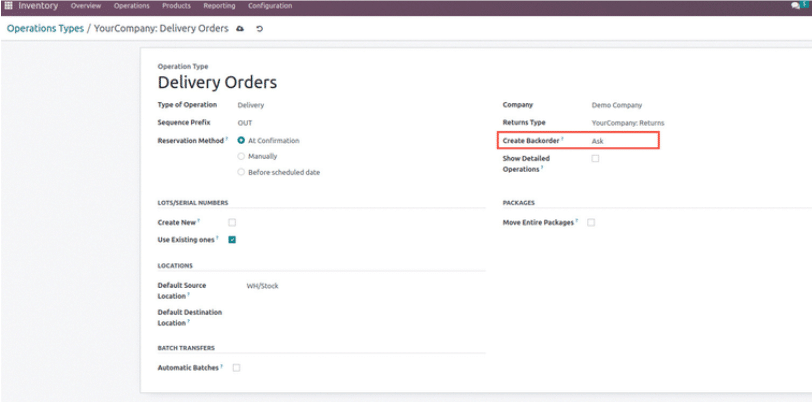

When the field is enabled, more options become accessible and are displayed below. The Automatic Batch Transfer option is available under the various operation types.

The Contact, Carrier, Destination Nation, and Destination Location choices are used to automatically group batches of data. The following option, Maximum lines per batch, ensures that transfers are not automatically added to batches that, if the transfer is added, will have more lines than this number. The next column is Maximum transfers per batch; if a transfer is added to a batch that will have more transfers than this number, it will not automatically be added to that batch. The next option is Auto confirmed, and the fields after that are Maximum weight per batch and Maximum transfers per batch.

Force Backorders

Backordering is the practice of allowing clients to place orders even when there is insufficient inventory on hand. Businesses employ backordering when a sudden increase in sales results in items selling faster than can be replenished. When they observe a boost in sales, retailers everywhere use it as regular practice.

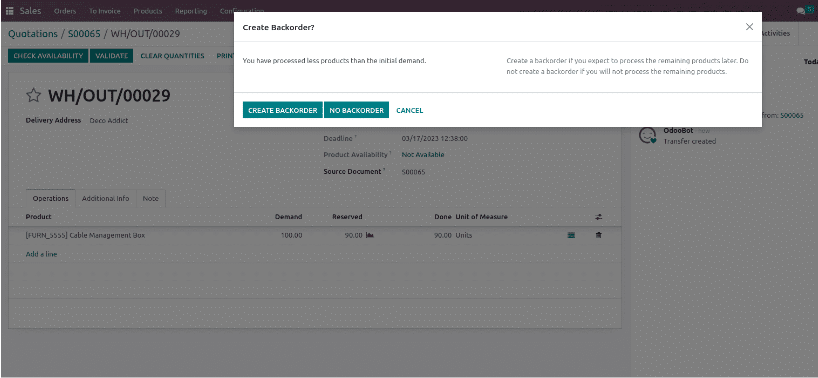

As illustrated below, Odoo 16 introduces a backorder option inside the operation types that allows users to select whether or not backorders are generated automatically.

The user can choose between three options under Create Backorder: Ask, Always, and Never.

A pop-up message that prompts you to create a backorder if you anticipate processing the remaining products later shows when the option is set to Ask. If you are not going to process the remaining products, do not create a backorder. as indicated below, when the user has processed fewer products than the initial demand.

The remaining products are automatically canceled when the option is set to Never, and a backorder is automatically generated for them when it is set to Always.

Inventory adjustments

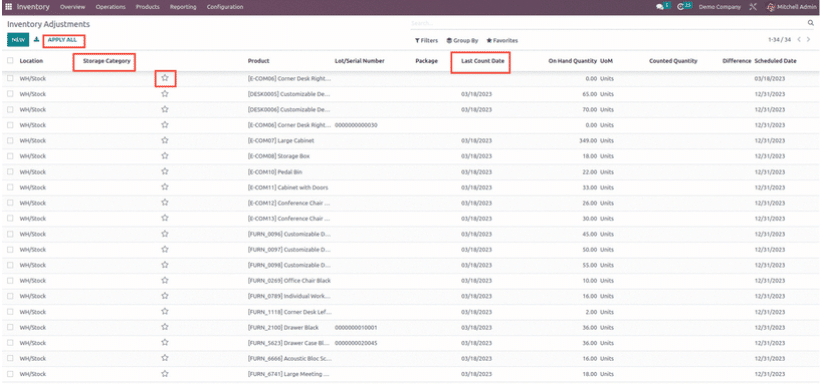

When adding an opening stock for the business and managing inventory, inventory adjustment is a crucial function. For any warehouse management system, real inventory counts in the warehouse can occasionally differ from reported inventory counts in the database. The difference between the two counts could be due to theft, harm, error on the part of the person, or other factors. Inventory adjustments must be made in order to correct the errors and ensure that the recorded counts in the database match the actual counts in the warehouse.

A filter for highlighted products, a “Apply all” option at the top of the screen, and other new features have been added to Inventory Adjustments in Odoo 16 as well as more storage categories and the Last count date.

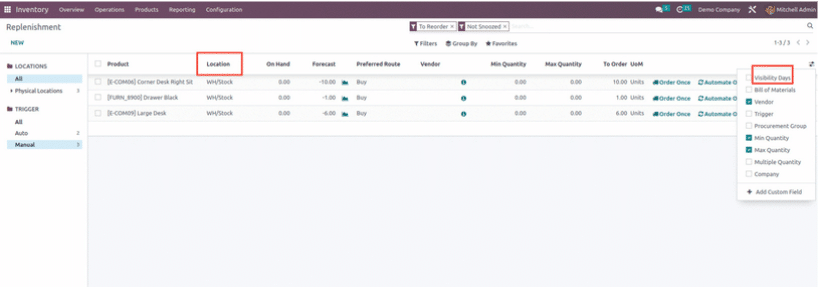

The process of replenishment involves managing inventory to maintain a sufficient level of supply. It is a common occurrence that is employed to effectively manage the retail sector. We need to restock to keep the merchandise flowing steadily. We also need to manage replenishment to stop the supplies from running out of stock.

With Odoo 16, the location option was also added to the replenishment function, allowing replenishment to be automated to a specific place. In addition, the visibility days of a replenishment rule can be configured to account for the quantity needed after the forecast date, as seen below.

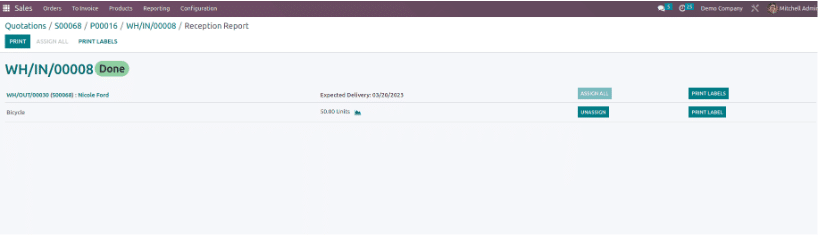

Reception report

The “Reception Report” can be enabled when you enter the Odoo Inventory module by selecting it from the Settings menu. It aids in the examination and distribution of received quantities.

By moving the auto-popup option to the operation type, Odoo 16 has improved the reception reports. This includes links to sales product names on labels, automatic display on barcodes, and other features.

Reporting and menus

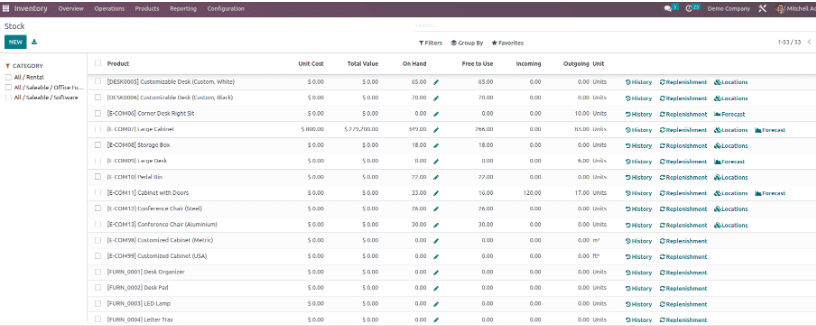

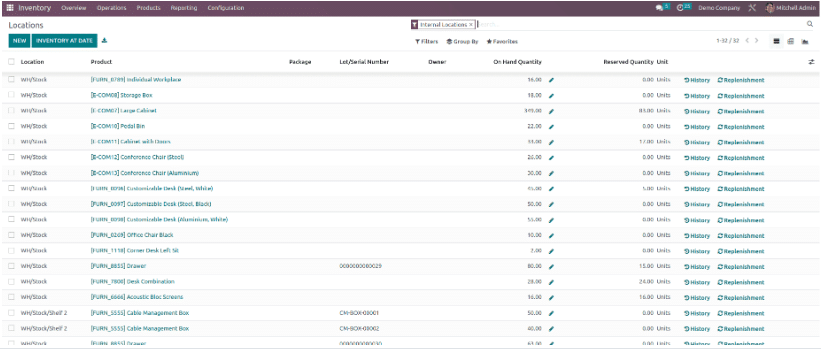

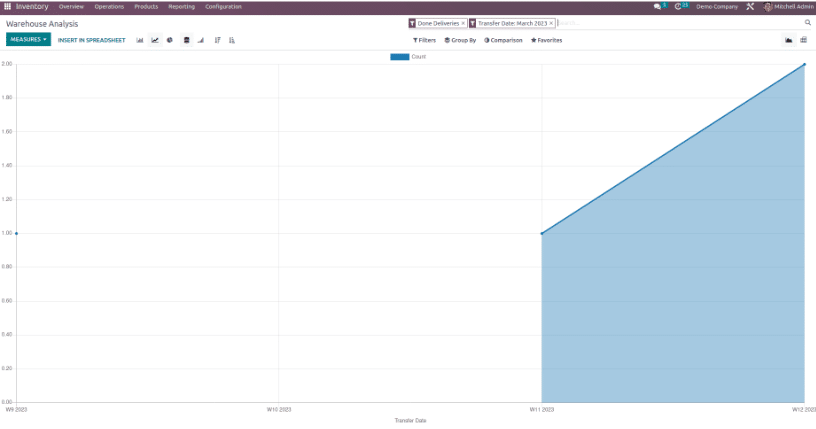

If the inventory operations are effectively monitored, one may easily evaluate and understand the method for managing the inventory. Odoo can give you access to a platform that is especially made for creating reports for the inventory activities performed in your company with accurate data representation in graphical and tabular forms. You can customize your reports in real-time to get complete results that suit your needs. Odoo 16 has updated all reports. have new menus and allow for simple switching between reports. The Odoo Inventory Module’s Reports menu is where you can access the reports for Stocks, Locations, Moves History, Stock Moves, Value, and Performance.

By selecting the Replenishment button on the screen, the product may be reordered in accordance with the reordering guidelines. The location of a product in your inventory will be shown through the Location button.

The list view of the Location report is shown below. The following information is shown here: Location, Product, Package, Lot/Serial Number, On Hand Quantity, and Reserved Quantity.

You can review the history of the actions and replenish the inventory by choosing the History and Replenishment buttons. Inventory changes can be made using the smart button on the screen.

To assess the effectiveness of warehouse operations, use the Performance button located in the Reports menu. Odoo will provide beneficial reports on the warehouse analysis that may be used later to boost efficiency.

Should I go for Odoo 16 Inventory module?

Yes, the Odoo 16 Inventory Module is a powerful and comprehensive tool that can greatly enhance your inventory management processes. With its new features, such as improved reporting, enhanced user experience, and better stock management capabilities, it can help you streamline your operations and stay ahead of the competition. Whether you run a small business or a large enterprise, the Odoo 16 Inventory Module can be a perfect fit for your inventory management needs. So, don’t wait any longer, try out the new features of Odoo 16 Inventory Module and take your inventory management to the next level.

Don’t hesitate to reach out to us for any inquiries or support related to the Odoo 16 Inventory Module. Our expert team is dedicated to helping you maximize the benefits of this powerful inventory management tool and ensure your business runs smoothly. Whether you have technical issues, need help with implementation, or have any other questions, we are here to help. So, get in touch with us today and take the first step towards improving your inventory management processes.