Informed decision-making is the lynchpin of a successful business strategy.

For this reason, it’s not surprising to discover that ERP software solutions are rapidly becoming as much a mainstay in the business arsenal as other ubiquitous software, such as CRM systems, with 53% of IT decision-makers polled by ComputerWeekly describing ERP as an “investment priority”. By 2026, the global ERP software market is expected to have grown to $78.41 billion.

ERP systems are the central nervous system of a well-integrated business operation. They allow for the automation and fine-tuning of core business processes while providing a consolidated data platform from which business leaders can glean invaluable insights into the operation of their business.

For manufacturers in particular, the impact of ERP is profound – one ERP implementation specialist reported that manufacturers who implemented ERP solutions managed to boast cost savings as high as 20%. It’s no surprise, then, that manufacturers are in fact the number one adopters of ERP software, with 67% describing their adoptions as “successful” or “very successful”.

The final decision on whether or not to implement an ERP system as a manufacturer will, of course, come down to these questions of added value – What’s the bottom line benefit your operation will receive from what is probably a time-consuming, labour-intensive and costly implementation process? For that, it helps to do a deep dive into what value an ERP system can add to your manufacturing process.

What can an ERP System do for Manufacturers?

ERP systems don’t just streamline and coordinate key business processes. They lift the lid on data insights that can be crucial in deploying new strategies or monitoring operations efficiency. In a field as cost-intensive as manufacturing, with its constant trade-off between inventory, output efficiency, wear and tear on machines, etc., having access to granular insights into the day-to-day workings of your operations can provide a truly transformative edge in business.

But what, precisely, does ERP actually offer manufacturers?

Visibility and Coordination – First and foremost, an ERP system provides a strategic overview of the entire manufacturing operation. An ERP system can dig down to deliver insights pertaining to inventory and stock levels; sales trends; production efficiency; quality yield / defect rate; overall equipment effectiveness, and more. These insights can arm business leaders with the information required to make strategic decisions; identify areas of weakness and opportunity; or evaluate business processes for improvement.

Automated Stock Control – ERP allows for the automation of systems pertaining to inventory management. An ERP system might, for instance, be set to trigger a purchase order on raw materials automatically, only when the stockpile of those goods reaches a certain threshold. This works two ways: that same system might then be programmed to initiate manufacturing processes to match output volume to current and predicted sales trends, so that a business never runs short of a hot ticket item.

Quotes & Estimates – Misquoting, even to a marginal degree, can have an eye-watering impact on a manufacturer’s bottom line. An ERP system can amalgamate disparate data sources to provide up-to-date and comprehensive cost estimates for comparison. This can be achieved through quote and estimate history kept on file; price optimisation; BOMs; up-to-date raw material costing; documented machine and labour costs; proven production rates based on past performance, etc. Combined, these data points can equip teams with the knowledge required to make accurate and current quotations, that do not risk undervaluing the work being done.

Actual vs. Standardised Costs – One immediate impact of a data-driven approach to price optimisation is that it allows businesses to re-evaluate standard pricing (which tends to lag behind real-world developments) by comparing it to actual costs of raw materials, labour, machine maintenance, and so on. Having the actual costs associated with your entire manufacturing process, from material purchases to final packaging and shipping, allows you to set a price that accurately reflects your business’ overheads.

Quality Control – A defective output good represents a 100% loss on investment. Even a defect rate of 2% through a manufacturing process can represent significant costs that an effective ERP system will be able to substantially mitigate. ERP software enables repeatable quality control steps to shave down your defect rate through the implementation of several measures, including: input goods inspection before downstream steps occur; monitoring of processes and triggering of alerts before issues arise; root cause analysis of detected issues recorded for future investigation/comparison corrective action processes documented and enforced within the system, etc.

How to Calculate the ROI of ERP for Manufacturers

These features read well on paper, and go some way to justifying the popularity of ERP implementation by manufacturing businesses all over the globe. But ultimately each of these measures, even bundled in a package, work together to produce just a single result – cost savings.

Implementing an ERP system, especially one with hardware communication capabilities to be able to pull data from and manage machinery on your production line, is a costly endeavour, both in up-front cost and the labour hours required for its thorough implementation.

What should a business leader keep in mind, then, when trying to calculate the return on investment for an ERP systems implementation program?

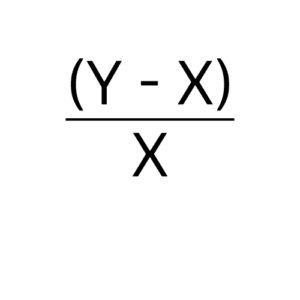

At its most basic, ERP systems are the same as any other system or process in business – they cost X amount of capital to implement, and generate Y amount of return in savings or direct revenue you expect to accrue as a result of the implementation. You can easily work out your ERP ROI quotient, expressed as a percentage, by entering these figures into the following simple formula:

Having a unified understanding of the costs associated with the implementation project between all departments and teams ensures consistency of financial reporting, and therefore an accurate assessment of the bottom-line cost to undergo the transformation.

Initial Costs – Beyond the vendor’s quote, a thorough understanding of all required modules in the software you intend to adopt will help you price in additional costs for customisation options, particularly if you intend your ERP solution to be able to interface with machinery on the shop floor.

Consultancy – Getting an ERP system that’s right for your manufacturing business means getting boots on the ground to understand your business’ unique processes and needs. A robust consultancy phase is usually how this is achieved. Carefully defining the consultants’ scope of work and labour hours in advance will help articulate the overall cost of this phase, and how it impacts on the cost to implement the system.

Maintenance – Don’t make the mistake of thinking that the cost of an ERP implementation is finalised once implementation is complete. You still need to consider periodic software updates; helpdesk support; enhanced functionality packages and hardware maintenance, as your ERP system is likely plugged into your machinery. These costs will be spread out, however, over the course of using the system, and not front-loaded during implementation.

Your ERP system itself, once fully operational, will be able to feed back data on cost savings to you directly, based on the processes outlined above. A thorough understanding of the cost of your implementation, and the data coming in from the system itself demonstrating ways your ERP system is making savings, will outfit you with the knowledge required to accurately calculate your ERP ROI quotient.

Discover how an ERP System could Transform your Manufacturing Processes

Could an ERP software solution unlock cost savings of up to 20% in your business’ manufacturing processes?

Target Integration’s specialist team of ERP software consultants are on call and ready to do a deep-dive into your manufacturing operations to unearth how an ERP solution could drive revenue and slash costs.

Ready to take a step towards your digital future?

Contact us today and book time with a consultant to realise your business’ full untapped potential!