Label and sticker printing is an extremely competitive business as this business stays relatively unaffected during most economical turmoil in industry. Thus it becomes more important for the owners of a printing business to integrate latest technology with their business to have an edge over their competitors.

This article makes clear as to how a label and sticker printing business can benefit by integrating an ERP.

Stage I: Collection of Raw material.

At this stage, ERP benefits you in two ways.

- It enables you to send requests for best quotations from your various sellers, in one easy click.

- It allows you to handle all the paperwork related to purchase, electronically, making it much faster, easier and error free.

Stage II: Inventory Optimization.

It is of utmost importance to any manufacturer that the stock is in his warehouse is used in an optimized manner. But this becomes even more important when the raw material is a product that might degrade over time or become easily outdated in view of new market innovations. This is true to a label and sticker printing company as well as newer and better inks, paper bases etc., keep venturing in the market.

An ERP helps you to track and optimize your inventory, keeping a check on your costs and enabling you to be up-to-date with your products.

Stage III: Estimation for printing and cutting.

When printing is done on a roll, various calculations need to be carried out concerning the size of the label or sticker, the margins to be provided and the length of the roll on which the printing is to be done. All these calculations can be easily done in an error free manner, saving your time and avoiding any wasted raw materials.

Stage IV: Tracking packaging of final goods.

After the products have been manufactured, you can control its whereabouts using an ERP system. This gives a clear picture to the concerned employees as to what they have to do with the ready products.

Stage V: Accounts and documents handling.

For the documents and accounts handling, most companies are using separate software, but with an ERP system you can have it all, in one software. Thus, you can easily integrate and centralize your business and have a better insight into all processes.

Besides an ERP system ensures no data or document loss, having it all stored in e-form.

All your customer invoice and related documents are generated and managed by an ERP

Stage VI: Transit tracking.

An ERP allows you to control not only the processes till manufacturing of your products but also the shipment part post manufacturing. With an ERP you can track your fleet, their movement and hence make any related decisions.

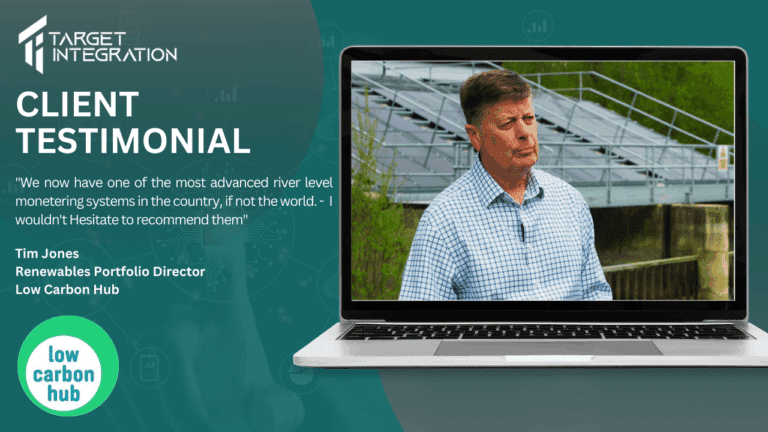

Target Integration is now working on developing an ERP for a huge label printing firm. If you wish to automate your business, contact us at [email protected]